The Ultimate Guide to R Type Thermocouple Applications in Industrial Settings

Introduction to R Type Thermocouple: Understanding the Basics

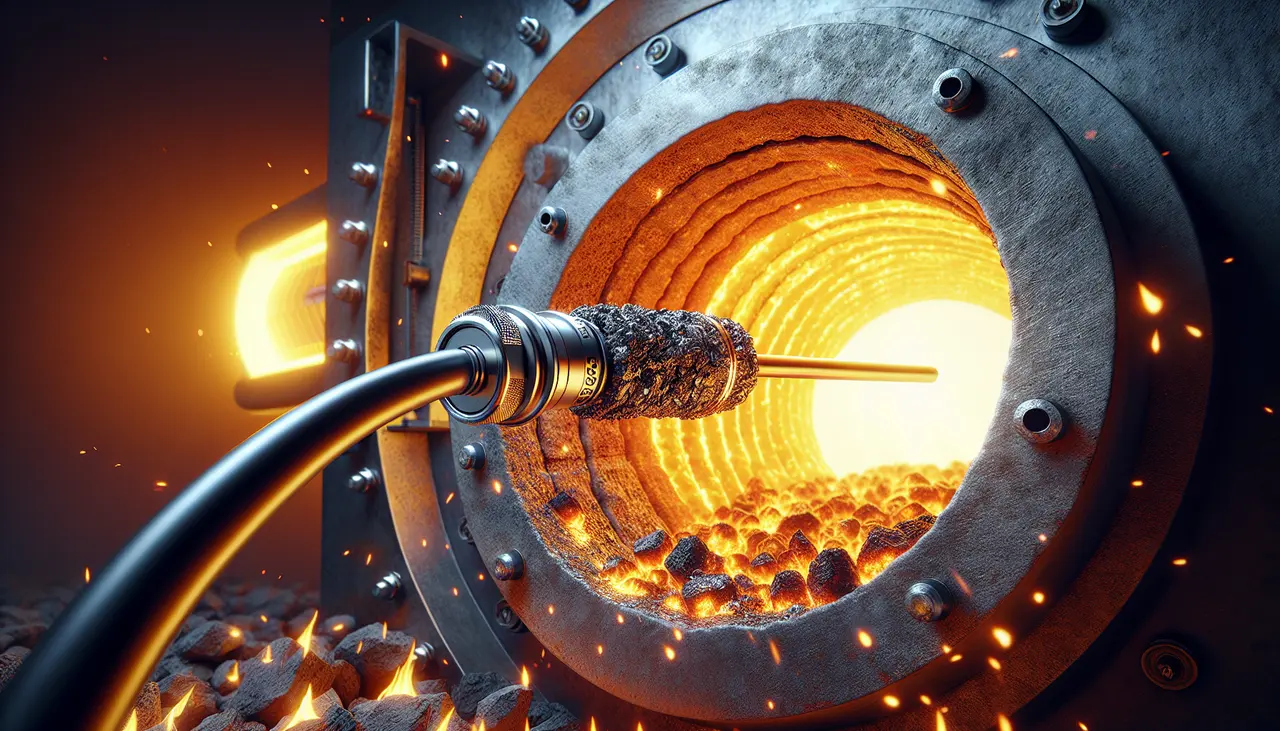

An R Type Thermocouple is a reliable tool for measuring high temperatures, making it a vital piece of gear in many industrial settings. Picture this gadget as your go-to thermometer, but instead of telling if you’ve got a fever, it’s built to handle extreme heat environments, like in metal processing or power generation plants. At its core, an R Type Thermocouple consists of two different metals joined at one end. When this junction gets hot or cold, it creates a small voltage. This voltage change is what tells us the temperature. Simple, right? Its strength lies in its ability to withstand temperatures up to 1600°C (2912°F). This rugged nature makes it perfect for jobs where regular thermometers would just give up. So, when precision and durability in measuring high temperatures are what you need, an R Type Thermocouple is your go-to instrument.

Key Features of R Type Thermocouples

R Type thermocouples are resistant warriors in high-temperature battlegrounds. They’re made from platinum-rhodium, which means they don’t give up easily when things get hot. Expect them to serve faithfully in temperatures up to 1600°C (2912°F). Because they’re platinum-based, they fight off corrosion like champions, staying accurate and reliable even when the environment gets aggressive with chemicals or oxidation. These thermocouples stand out for their precision. They’re the go-to choice when you need measurements you can trust, thanks to their low drift. Low drift means they don’t change their behavior much over time, so the temperature they tell you today is going to be just as trustworthy tomorrow. They may cost more upfront, but their durability and accuracy make them worth their weight in platinum in the long run. When it’s a battle against high temperatures and harsh conditions, the R Type thermocouple is a true ally.

The Role of R Type Thermocouples in Temperature Measurement

R type thermocouples are the unsung heroes in the industrial world when it comes to measuring temperature. They’re made of platinum and rhodium, which might sound fancy, but what it really means is that they can handle a lot of heat. We’re talking about temperatures ranging from 1,600 to 1,700 degrees Celsius. That’s hot enough to melt most metals. So, where do you find R type thermocouples doing their thing? In places like steel factories, glass production plants, and any other spot where knowing the exact temperature is the difference between quality products and a molten mess.

Here’s why industries rely on them so much. First off, they’re reliable. In environments where accuracy is non-negotiable, R type thermocouples keep readings spot on. Plus, they’re built tough. These thermocouples can stand the heat and maintain their performance over time, which is a big deal when downtime means lost money. And here’s the kicker, they’re adaptable. With the ability to integrate into various industrial processes seamlessly, R type thermocouples prove to be versatile players on the manufacturing floor. Simply put, they’re at the core of making sure everything runs at the right temperature, proving that sometimes the most crucial tools in industry are the ones measuring the heat.

Major Industrial Applications of R Type Thermocouples

R Type Thermocouples are hard workers in industrial settings, measuring high temperatures where other sensors can’t handle the heat. They are made of platinum and rhodium, which means they’re not only accurate but durable too. These thermocouples shine in a few key areas. First, they’re a big deal in the metal production industry, especially with steel and iron. Their ability to withstand temperatures up to 1,600°C makes them perfect for monitoring molten metal. Next up, power generation plants rely on them to keep things running smoothly. They help in measuring the temperature of gases and steam, which is crucial for efficient power production. The glass industry also benefits from R Type Thermocouples. Making glass requires precise temperature control, and that’s where these thermocouples come into play, ensuring the material is heated evenly. They’re not just about measuring temperature; they play a vital role in maintaining the quality and safety of industrial processes. So, whether it’s about keeping an eye on molten metal or ensuring steam is just the right temperature, R Type Thermocouples are up for the challenge.

Advantages of Using R Type Thermocouples in Industrial Settings

R Type thermocouples are a go-to for measuring temperatures in industrial settings for several strong reasons. First off, they’re known for their high accuracy. In environments where even a small mistake in temperature readings can lead to big problems, this precision is crucial. They can accurately read temperatures up to 1600°C, which covers a wide range of industrial applications. Another big advantage is their longevity. These thermocouples are made with platinum and rhodium, making them not just durable but also stable over long periods. This means less frequent replacements and, in the long run, cost savings. They’re also versatile. Whether you’re dealing with the heat treatment of metals, glass production, or power generation, R Type thermocouples are suitable for a broad spectrum of high-temperature industrial environments. Lastly, the minimal drift feature. Over time, some thermocouples might show changes in their readings, but R Types maintain their accuracy, ensuring reliable data over many uses. So, if you’re after precision, durability, and cost-effectiveness in high-temperature industrial settings, R Type thermocouples are a smart choice.

Installation Tips for R Type Thermocouples in Various Industrial Environments

When installing R Type thermocouples in industrial environments, keep it simple yet thorough. First, make sure you’ve got the right tools and you understand the environment you’re working in. Different settings have different needs; for example, a high-temperature area needs thermocouples made from platinum and rhodium to withstand the heat. Always check the maximum temperature your thermocouple can handle before installation. Make sure to install the thermocouple so it directly contacts the area or process you’re measuring. Poor contact means poor temperature readings. In environments with a lot of electrical noise, like near large machines or power lines, shield your thermocouple wires or use twisted pair cables to reduce signal interference. Also, remember to regularly calibrate your thermocouple to ensure accuracy over time. Keeping these tips in mind will help you get reliable, accurate temperature measurements across different industrial settings.

How to Choose the Right R Type Thermocouple for Your Application

Choosing the right R Type thermocouple for your application comes down to understanding your specific needs. R Type thermocouples are known for their reliability and accuracy in high-temperature applications, making them ideal for industries like metallurgy, glass production, and ceramics.

First, consider the temperature range of your application. R Type thermocouples can measure temperatures up to 1600°C (2912°F). If your operations go beyond this range, this thermocouple might not be the best fit.

Next, think about the environment. Is it corrosive or under high pressure? R Type thermocouples are platinum-rhodium, making them more resistant to oxidation and better suited for cleaner environments. For harsher conditions, you might need a thermocouple with a protective sheath or choose a different type altogether.

Finally, factor in response time and sensitivity. R Type thermocouples provide stable readings and are less prone to drift, but if your process requires rapid temperature changes detection, you might want to explore options with faster response times.

In short, choosing the right R Type thermocouple requires you to balance your temperature range needs, environmental conditions, and desired response time. Knowing these will guide you in making a decision that ensures accuracy and longevity in your temperature measurements.

Maintenance and Calibration: Keeping Your R Type Thermocouple in Top Condition

Maintaining your R type thermocouple ensures it gives accurate readings and remains reliable for industrial tasks. First, regular cleaning is a must. Remove any buildup that could affect its performance. Next, avoid mechanical stress. Don’t bend or drop your thermocouple, as it could damage the sensor. Calibration is also key. Over time, even the best thermocouples drift from accurate readings. Calibrate yours regularly against a standard to ensure its measurements are correct. Remember, the environment matters. High temperatures and corrosive substances can degrade your thermocouple faster. Protect it by choosing the right casing material and replacing it when signs of wear appear. Lastly, keep a record of performance and maintenance. It helps in diagnosing issues and planning future recalibrations. Stick to these tips, and your R type thermocouple will serve you well, ensuring precision in high-temperature industrial applications.

Troubleshooting Common Issues with R Type Thermocouples

R Type thermocouples, known for their reliability in high-temperature applications, sometimes hit a bump in their performance. When they do, knowing how to troubleshoot can save you time and money. First, check the connection points. Loose connections are often the culprit. Tighten them up and see if that fixes the issue. If not, inspect the thermocouple for any signs of wear or corrosion. These conditions can affect its accuracy. Another common issue is incorrect installation. Make sure the thermocouple is positioned correctly in your industrial setup, not too close to heat sources that might skew its readings. Lastly, electromagnetic interference from nearby equipment can mess with the signal. Consider rerouting wires or shielding the thermocouple to protect its readings. Keeping these tips in mind can help maintain the precision and reliability of your R Type thermocouples.

Conclusion: Maximizing Efficiency with R Type Thermocouples in Industrial Applications

In wrapping up, R Type thermocouples emerge as a titan in industrial temperature measurement, offering remarkable stability and accuracy in high-temperature settings. Their resilience in the face of extreme environments makes them indispensable for maximizing efficiency in processes like metal production, power generation, and glass manufacturing. The proper use of R Type thermocouples, leveraging their high-temperature capabilities and longevity, can significantly dial up operational efficiency and ensure product quality in these demanding sectors. Remember, matching the thermocouple to the specific application is key—choosing R Type is opting for reliability and precision in your high-temperature industrial applications.