Description

|

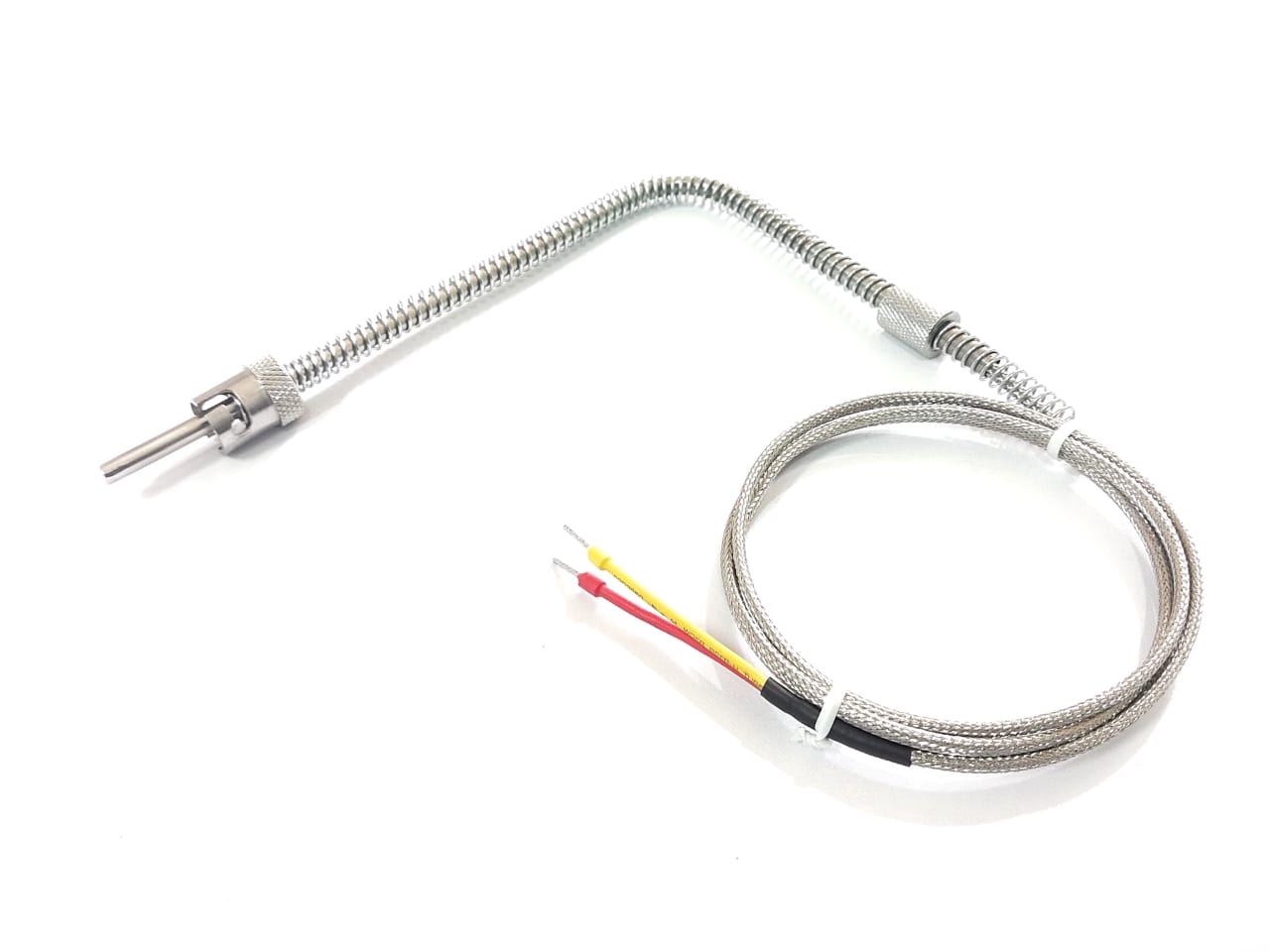

Type |

J/K ( Simplex ) |

|

Temperature Range |

Up to 800⁰C |

|

Sheath |

0.5 / 1 / 1.5 / 2 mm |

|

Sheath Material |

SS310 / SS316 / Inconel |

|

Joint Material |

Plastic / SS potseal |

|

Wire Length |

1 / 1.5 / 2 / 2.5 / 3 mtr |

- A hot runner thermocouple is a type of temperature sensor that is used to monitor and control the temperature in hot runner systems used in plastic injection molding.

- A hot runner system is a series of heated components that keep the plastic in a molten state as it flows through the mold, which allows for faster production cycles and better quality parts. The hot runner thermocouple is used to measure the temperature in the hot runner system and provide feedback to the temperature control system, which adjusts the temperature of the heating elements to maintain a consistent temperature.

- Hot runner thermocouples are typically designed to withstand high temperatures and the corrosive effects of the molten plastic. They are often made with Type K or Type J thermocouple elements, which are composed of alloys that can withstand high temperatures.

- The thermocouple is usually mounted directly into the hot runner system and is protected by a metal or ceramic sheath to prevent damage from the high temperatures and corrosive environment. The accuracy and response time of a hot runner thermocouple depend on the type of thermocouple element, the sheath material, and the overall design of the thermocouple.

- Proper installation and maintenance of the hot runner thermocouple is critical to ensure accurate and reliable temperature measurement in plastic injection molding applications. If the temperature is not properly monitored and controlled, it can result in poor quality parts, increased scrap, and damage to the mold or hot runner system.