How Custom Control Panels Can Transform Your Operational Efficiency

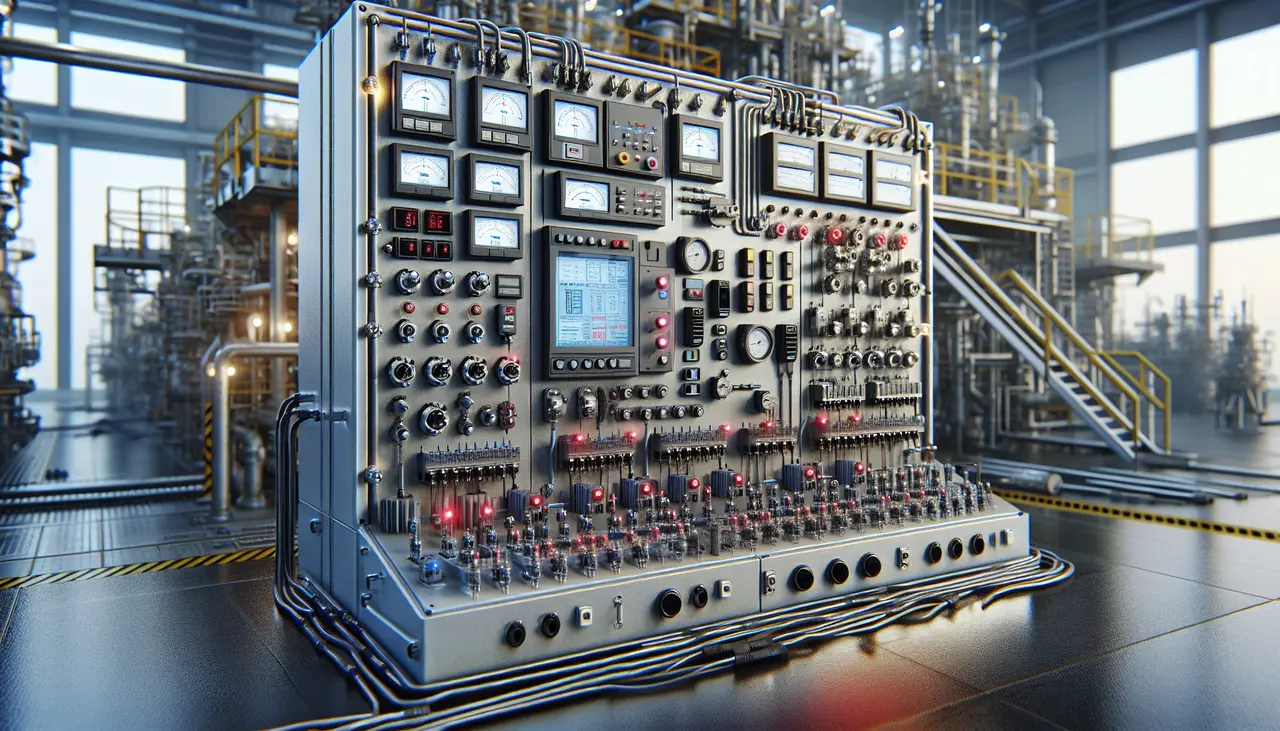

Introduction to Custom Control Panels

Custom control panels are essentially the brain of your operation. They let you control the machines and processes specific to your business with precision and ease. Imagine having a remote control that can manage every aspect of your operation – that’s what a custom control panel does. It’s designed specifically for your needs, which means it fits your operation like a glove. With these panels, you’re not trying to make a generic solution work for you. You’re getting something built with your exact specifications in mind. This means more efficiency, less waste, and ultimately, a smoother running operation. Whether you’re in manufacturing, processing, or any industry needing precise control, custom control panels can significantly upgrade how you operate. They’re not just an expense; they’re an investment in making your operation leaner, faster, and more competitive.

The Importance of Operational Efficiency in Today’s Industries

Operational efficiency isn’t just a fancy phrase; it’s the lifeblood of any successful industry today. Think about it like this: the smoother your operations run, the less time and money you waste, and the more you can focus on growing your business. Every minute saved on a task adds up, and before you know it, you’re operating faster, better, and cheaper than the competition. This is where custom control panels come into play. They are like the behind-the-scenes heroes, tailored to fit your exact needs, making sure every part of your operation communicates perfectly and runs without a hitch. From manufacturing to utilities, efficient operations mean fewer errors, less downtime, and a healthier bottom line. So, the importance of operational efficiency? It’s not just important; it’s essential.

How Customised Control Panels Enhance Operational Efficiency

Custom control panels are not just boxes with wires; they are the brains behind your operations. They are designed to meet your specific needs, turning complicated tasks into smooth, automated processes. Here’s how they enhance operational efficiency: First, they are tailored to fit your operation. No more one-size-fits-all solutions that don’t quite work. Every function and feature is designed with your workflow in mind, eliminating unnecessary steps and making your processes more straightforward. Second, they reduce downtime. With systems optimized to run more efficiently, there’s less wear and tear on your machinery. This means less time fixing things and more time doing things. Also, these panels can be programmed to alert you before something goes wrong, allowing for preventative maintenance instead of emergency repairs. Third, custom control panels can integrate with your existing systems, making everything work together seamlessly. No need to replace what you already have; custom panels are built to complement and enhance your current setup. Lastly, they improve safety. Designed with the latest standards in mind, custom control panels help ensure that your operations are not just efficient, but safe for everyone involved. In short, custom control panels streamline your processes, cut down on downtime, integrate seamlessly, and keep safety in check. That’s smarter working, with less effort.

Key Features of Custom Control Panels

Custom control panels are tailored exactly to what your operation needs, nothing more, nothing less. This focused approach is what gives them an edge. They come packed with features that could make a huge difference in how efficiently your setup runs. Here’s what sets them apart: Flexibility in design means these panels are built to fit your exact requirements. Whether you need to control a single machine or an entire manufacturing line, they can be made to order. High compatibility with existing systems is another plus. These panels can seamlessly integrate with what you already have, reducing the need for extensive modifications or new equipment. Enhanced safety features ensure that operations not only run smoothly but also safely. Custom panels can include failsafes and emergency stop features specific to your needs. Lastly, ease of use is a big deal. Since they’re designed with your operation in mind, these panels are user-friendly, making training staff straightforward. With these key features, custom control panels push your operational efficiency to the next level by making things run smoother, safer, and smarter.

Customization Options for Control Panels and Their Impact

When considering custom control panels, the range of customization options is vast and can significantly impact operational efficiency. You can choose the type and arrangement of components, materials, and even the software that runs the panel. Here’s a breakdown:

- Components: Depending on your needs, you can select various switches, buttons, displays, and more. Tailoring these to your specific operations can streamline tasks.

- Materials: Durability and environmental resistance can be enhanced by choosing robust materials suited to your workspace, be it a factory floor or an outdoor installation.

- Software: Custom software allows you to improve the interface interaction, making it intuitive and responsive, shaving off precious seconds or even minutes from operation times.

- Design: Ergonomic design ensures that the panel is comfortable to use, reducing user fatigue and errors.

By selecting the right combination of these options, you can create a control panel that not only fits perfectly with your operational needs but also boosts efficiency and productivity. Optimizing the user interface and the physical layout can lead to quicker responses, lower the chance for errors, and increase the overall speed of operations. Remember, every decision in customization should be driven by your specific operational goals to ensure the most significant impact.

Case Studies: Operational Transformations with Custom Control Panels

Businesses everywhere are constantly on the hunt for ways to boost their operational efficiency, and custom control panels have emerged as a game-changer in this arena. Let’s dive into a few case studies to see how these panels are making real differences. First up, a manufacturing plant that struggled with outdated machinery. By integrating custom control panels designed specifically for their needs, they were able to automate processes that previously required manual input, significantly cutting down production time and reducing errors. The result? A 30% increase in efficiency and a happier workforce. Next, consider a large retail chain that was facing inconsistencies in managing its HVAC and lighting systems across multiple locations. After switching to custom control panels, not only were they able to centralize control, but they also benefited from significant energy savings. In fact, their energy bills saw a dramatic drop of 25% within the first six months. Lastly, a small but fast-growing online retailer invested in custom control panels to manage its order fulfillment process. The tailored panels helped streamline their packaging and shipping operations by automating sorting and labeling, slashing the time it took to get orders out the door. The impact? A 50% boost in order processing speed and a notable increase in customer satisfaction rates. These case studies underscore how custom control panels are not just about pushing buttons; they’re about pushing boundaries—transforming operations in ways that directly contribute to the bottom line and overall efficiency. Whether it’s manufacturing, retail, or any sector in between, the message is clear: customizing control can lead to operational transformation.

Integration with Existing Systems and Infrastructure

When you bring custom control panels into your operations, you’re not just adding another piece of equipment; you’re seamlessly integrating powerful tech into your existing systems and infrastructure. One of the key benefits here is that custom panels are designed to work hand in hand with what you already have in place. This means there’s no need to overhaul your entire setup or worry about compatibility issues. Custom panels are tailor-made to fit your specific needs, whether that involves unique operating environments, specific technological requirements, or particular integration capabilities. This streamlined integration boosts operational efficiency by ensuring that all parts of your system communicate effectively, reducing downtime and increasing productivity. Plus, by working with your existing setup, custom control panels save you time and money, both in the short term and down the line. In essence, they’re not just fitting into your system; they’re optimizing it.

The Role of Technology in Advancing Control Panel Capabilities

Technology isn’t just changing the game; it’s rewriting the rules, especially when it comes to control panels. With advances in tech, custom control panels have become smarter, more efficient, and a ton easier to use. Here’s the scoop: modern control panels can now automate processes that used to require manual intervention. This means machines can adjust themselves on the fly, minimizing errors and boosting efficiency. Plus, with IoT (Internet of Things) integration, these panels can be monitored and controlled from virtually anywhere, as long as you have an internet connection. This connectivity not only improves response times to issues but also enables predictive maintenance. By analyzing data trends, systems can alert you to potential problems before they cause downtime. In short, technology is empowering control panels to be more responsive, predictive, and adaptive, which, in turn, can significantly improve your operational efficiency. It’s not just about pushing buttons anymore; it’s about smart systems doing the heavy lifting for you.

Cost-Benefit Analysis of Investing in Custom Control Panels

Investing in custom control panels might seem like a big step, but it’s one that comes with its own rewards. The initial cost often sits higher than standard panels due to the personalized design and specific components. But let’s break it down. Custom panels are tailored to fit your operation’s exact needs. This means you’re not spending on features you don’t need or lacking ones you do. Over time, this tailored approach can lead to significant savings in operation costs. Energy efficiency is another big win. Custom panels can be designed to optimize power use, leading to lower energy bills each month. Then, there’s downtime. With a system built specifically for your operation, the risk of malfunctions and downtime can decrease, keeping your workflow smooth and uninterrupted. Although the upfront investment might pinch, the long-term savings and efficiency gains make a compelling case. Custom control panels don’t just cost, they pay.

Conclusion: Revolutionizing Your Operations with Custom Control Panels

In wrapping up, diving into custom control panels isn’t just a minor upgrade; it’s a game-changer for your operations. Think about it: you’re tailoring technology to meet your exact needs, cutting out any unnecessary fluff. It’s about getting what works for you, optimizing your processes, and pushing efficiency to its limits. Imagine having controls that fit your operations like a glove, reducing errors, and speeding up production. The difference is clear – custom control panels aren’t just an investment in technology, they’re an investment in the future of your operations. From streamlining tasks to enhancing safety, these panels bring a level of precision and reliability that generic solutions can’t match. So, revamping your operations with custom control panels is more than upgrading; it’s about setting a new standard for success in your industry.