Maximizing Efficiency: The Role of Advanced Control Panel Solutions in Manufacturing

Introduction to Control Panel Solutions in Manufacturing

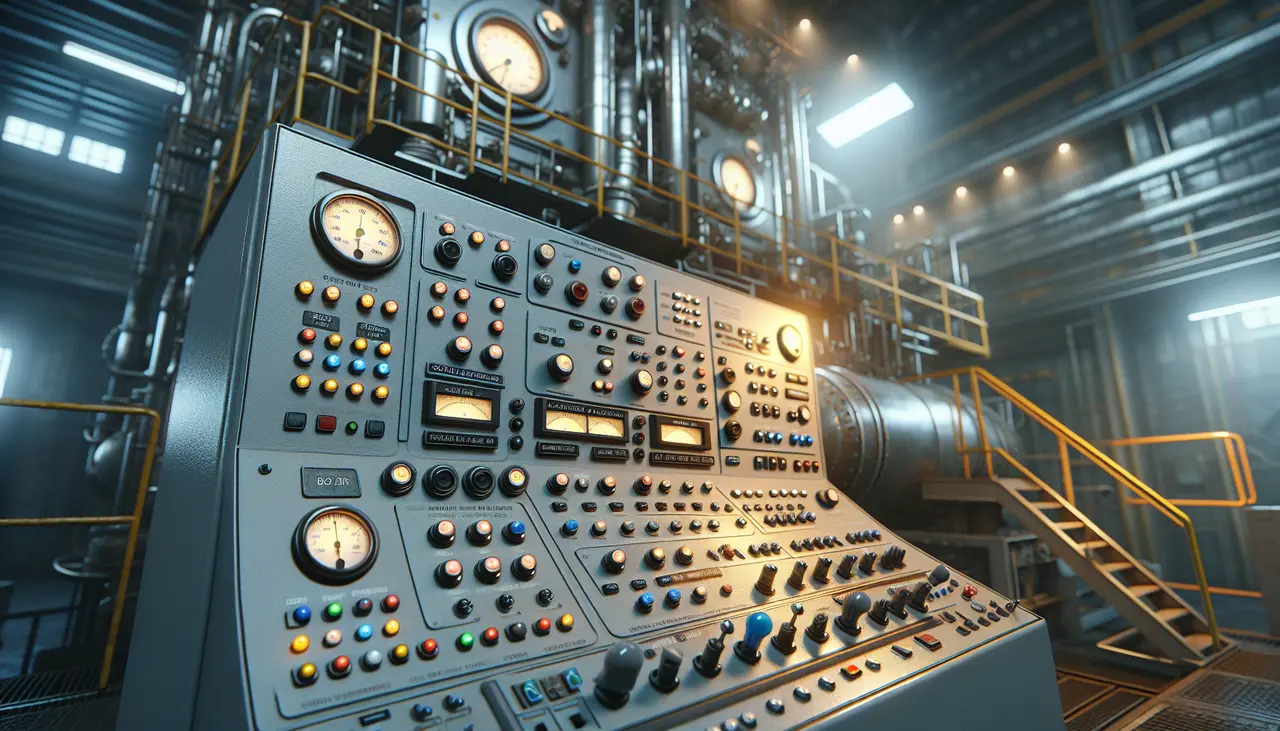

In manufacturing, control panel solutions are the brains of the operation. They manage the machines, making sure everything runs smoothly and efficiently. Think of them as the command center for production lines. Without them, machines wouldn’t know when to start, stop, or how to behave under different conditions. These panels can range from simple setups controlling a single machine to complex systems overseeing the entire manufacturing process. The goal is always the same: keep things moving without wasting time or resources. Whether it’s turning raw materials into parts or assembling those parts into a finished product, control panels make it happen. They monitor conditions, make decisions in real time, and adjust actions based on what’s needed. This not only helps in maximizing efficiency but also ensures consistent quality in the end product. In essence, the right control panel solution can be a game-changer in manufacturing, making operations smarter, faster, and more reliable.

The Importance of Efficiency in Manufacturing

In manufacturing, being efficient isn’t just a goal; it’s the heartbeat of the operation. Efficiency means making the most out of your resources, including time, materials, and energy. When a plant operates efficiently, it produces more with less, cutting down on waste and saving money. This isn’t just about speeding up production lines or pushing workers harder. It’s about smarter work. It’s about using advanced technology, like control panels, to streamline operations, reduce errors, and ensure everything runs like a well-oiled machine. An efficient manufacturing setup can respond faster to market changes, maintain high quality, and keep costs in check. In a world where competition is fierce, efficiency might just be the difference between leading the pack and struggling to keep up.

What Are Advanced Control Panel Solutions?

Advanced Control Panel Solutions are the brains behind the machines in a manufacturing setup. They’re like the mastermind that makes sure everything runs smoothly, on time, and without hiccups. In simple terms, these panels are complex assemblies that control machines, production lines, and entire plants, ensuring that manufacturing processes are as efficient as possible. They monitor conditions, manage operations, and provide crucial data to help prevent downtime. Think of them as the control tower at an airport but for manufacturing. Advanced panels can adapt to changes, make quick decisions, and keep everything moving flawlessly. Whether it’s controlling a single machine or orchestrating a full-scale production line, these solutions are key to making manufacturing smarter, faster, and more reliable.

Key Features of Cutting-Edge Control Panel Solutions

Cutting-edge control panel solutions are all about making manufacturing processes smarter, faster, and more reliable. First off, they’re designed to be highly customizable. This means you can tweak them to fit the exact needs of your production line. No more, no less. They also boast top-notch automation capabilities. Imagine having machines that adjust on the fly without human help. That’s efficiency at its best. Next, they’re built with the future in mind, supporting upgrades and expansions. Your setup today won’t be obsolete tomorrow. Lastly, these panels are equipped with real-time monitoring and analytics. This feature is a game-changer. You get data on everything happening on the shop floor at your fingertips. Spot issues fast, make informed decisions, and keep everything running smoothly. In short, the best control panel solutions are like the Swiss Army knife for modern manufacturing – versatile, smart, and always ready to take on challenges.

How Control Panel Solutions Enhance Manufacturing Efficiency

Control panel solutions are game changers in the manufacturing world. Here’s the thing – they streamline operations and boost efficiency like nothing else. Imagine having a brain central to your manufacturing process that can control, manage, and monitor everything. That’s what these panels do. They make complex processes simpler and quicker. With the right control panel in place, factories can automate tasks that once needed manual intervention. This means machines work smarter, not harder, and they’re doing it round the clock. Downtime? It’s minimized. Production speed? Amped up. And the best part? Quality remains top-notch because everything is calibrated to precision. So, whether you’re crafting cars or concocting pharmaceuticals, control panels help ensure that each product rolling off the line is as good as the one before.

Integration of Control Panels with Manufacturing Processes

In manufacturing, the heart of the operation is often its control panel systems. Imagine them as the brain of the whole production line. By integrating advanced control panels with manufacturing processes, businesses are stepping into a new era of efficiency. These systems are not just switches and buttons; they are smart. They can monitor processes, make adjustments in real-time, and even predict possible hiccups before they occur.

Let’s break it down simply. When a control panel is perfectly synced with a manufacturing process, it’s like having the best conductor lead an orchestra. Every component, from assembly lines to packaging, works in harmony. This means less time fixing errors and more time producing quality products. The results? Faster production times, lower costs, and higher product quality.

In essence, integrating advanced control panels into manufacturing processes is like giving the operation a brain upgrade. It’s smarter, quicker, and more efficient, which in today’s fast-paced market, is not just nice to have; it’s essential.

Case Studies: Success Stories of Control Panel Solutions in Industry

Companies worldwide have seen big wins by upgrading to advanced control panel solutions. Let’s look at a few examples. A car manufacturer in Germany switched to a state-of-the-art control panel system. The result? Their production speed shot up by 30%, and they cut down errors by an impressive 50%. Next, a bottled water company in the USA made the leap to automated control panels. They managed to increase their production rate by 25% and reduced energy costs by 20%. Then there’s a textile company in India. After integrating smarter controls, they enhanced their product quality, reduced waste by 40%, and boosted overall efficiency. These stories aren’t just numbers. They highlight how investing in the right technology can drive companies forward, making them faster, smarter, and more cost-effective.

Challenges and Solutions in Implementing Advanced Control Panels

Adopting advanced control panels in manufacturing isn’t just about buying new technology and plugging it in. Companies face real challenges, from high initial costs to training staff. However, the efficiency and long-term savings they bring can’t be ignored. Let’s break it down. High costs scare many, but the return on investment from streamlined operations eventually offsets this. Training staff seems daunting, yet with today’s user-friendly interfaces and available training programs, it’s more manageable than ever. Compatibility issues may arise with existing systems, but solutions often lie in choosing adaptable control panels or working with integrators to ensure smooth transitions. Fear of change is natural, but the leap towards advanced control panels can significantly improve manufacturing efficiency, making it well worth overcoming these hurdles.

Future Trends in Control Panel Technology for Manufacturing

As we look toward the future, control panel technology in manufacturing is leaning towards smarter, more efficient solutions. Expect to see a rise in the use of IoT, or the Internet of Things, where devices connect and communicate to streamline processes. This means control panels will not just control machinery but also predict maintenance needs and optimize production in real time. Another big trend is the integration of artificial intelligence (AI) and machine learning. These technologies will allow control panels to learn from data, making decisions that increase efficiency and reduce waste. Also, look out for more touch-screen interfaces and wireless communication options, making control panels more user-friendly and flexible. As manufacturers aim for greener operations, energy-efficient control panels that reduce power consumption will become standard. In a nutshell, the future of control panel technology is all about connectivity, intelligence, and sustainability.

Conclusion: The Impact of Control Panel Solutions on Manufacturing Efficiency

Control panel solutions are not just boxes of wires and buttons; they’re the nerve center of manufacturing efficiency. By integrating advanced control panels, manufacturers tap into a world of opportunities for enhancing productivity and slashing operational costs. Here’s the thing – it’s about doing more with less in today’s competitive market. Advanced control panels bring precision, speed, and intelligence to the production line. They minimize human error, reduce downtime, and enable predictive maintenance, which is like fixing a machine before it even breaks down. So, it’s clear: investing in cutting-edge control panel solutions is not an expense but an investment in the future of manufacturing. Bottom line, if you’re aiming for the top in manufacturing, these panels are not optional; they’re essential.