How Customize Power Distribution Panels Are Changing the Face of Manufacturing

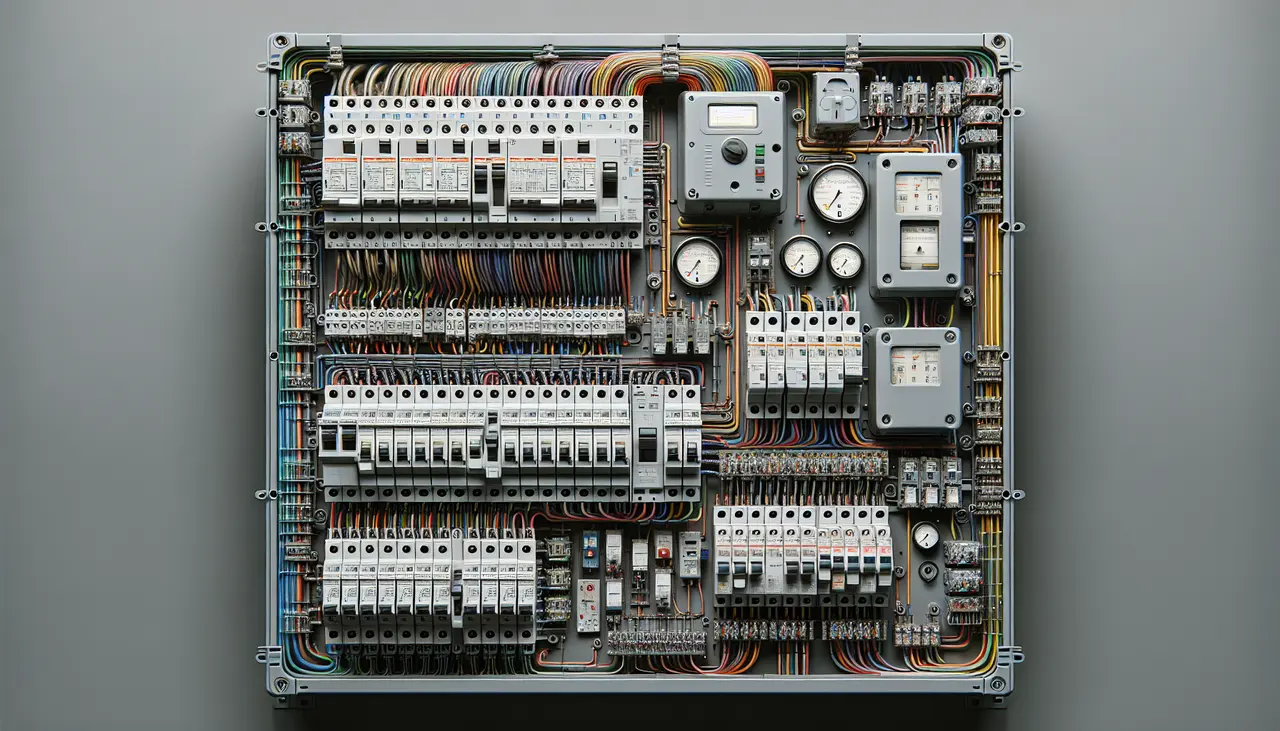

Introduction to Power Distribution Panels in Manufacturing

In the heart of every manufacturing facility beats a crucial system that decides how effective and efficient the operation can be – the power distribution panel. Think of it as the quarterback in football, calling the plays for where electricity needs to go throughout the plant. These panels aren’t just metal boxes; they’re the brains behind ensuring that each piece of machinery gets the exact amount of power it needs to operate without a hitch. This is no small feat considering the diverse array of equipment used in manufacturing today, from the delicate electronics in assembly robots to the brawny motors driving conveyor belts. With custom power distribution panels, factories are not just managing power; they’re optimizing their entire production process to be as smooth and efficient as possible. This bespoke approach means that whether a manufacturer is stamping car parts or assembling smartphones, they have a power distribution system tailored exactly to their needs, ensuring they can produce more, waste less, and keep innovation on the fast track.

The Evolution of Power Distribution Panels

In manufacturing, power is everything. It runs the machines, keeps the lights on, and ensures production never stops. This is where power distribution panels come into play. They’re the backbone, distributing electricity from one source to multiple outputs efficiently. But, like everything in tech, they’ve evolved. Back in the day, these panels were one-size-fits-all, which often meant manufacturers had to adapt their operations around the limitations of these panels. It was far from ideal. Now, we’re seeing a shift towards custom power distribution panels. This is a game-changer. Manufacturers can now have panels tailored to their specific needs. Need more power in one area of the factory? Done. Require special safety features? Consider it included. This customization leads to increased efficiency, better safety, and even cost savings over time. And that’s not even touching on the innovation it allows. Being able to design your power supply around your needs, not the other way around, means manufacturers can push the boundaries of what’s possible. The evolution of power distribution panels is not just about better electrical infrastructure; it’s about empowering manufacturers to innovate, improve, and lead in their industries.

Customization: Tailoring Power Solutions to Industry Needs

Each manufacturing plant has unique energy needs, and custom power distribution panels are stepping in to fill that gap. Instead of a one-size-fits-all approach, customization allows businesses to tailor their power solutions precisely to their specific requirements. This means whether a company is dealing with high-demand machinery, sensitive equipment, or a need for scalable energy options, there’s a power distribution panel designed to meet those needs. Custom panels come with the flexibility to adjust for current load requirements and future expansions. This adaptability not only ensures efficiency and reliability but also cuts down on energy waste, making operations smoother and more cost-effective. The real beauty of customization lies in its ability to harmonize with the industry’s evolving landscape, ensuring that businesses are always powered for success, no matter the challenge.

How Custom Power Distribution Panels Enhance Efficiency

Custom power distribution panels are big game changers in manufacturing, making things run smoother and faster. Here’s the deal: by tailoring these panels to specific needs, factories can cut down on energy waste. This means machines only get the juice they need, nothing more, nothing less. It’s like having a smart system that knows what’s needed where, and that’s a direct hit to boosting efficiency. Less energy waste equals less spending on power, and that’s good news for any operation’s bottom line. Plus, with everything dialed in just right, machines run better and break down less often, keeping production lines moving fast. In summary, custom power distribution panels help factories save money, reduce downtime, and get more done. It’s a win-win-win.

The Role of Technology in Custom Power Distribution Panels

In the world of manufacturing, custom power distribution panels are a big deal, and technology is the hero in this story. These panels ensure that electricity is spread out exactly where it’s needed, without any waste or hassle. It’s like having a smart system managing your power supply. Thanks to advancements in technology, these panels can now be tailor-made to fit specific needs. This means whether you’re running a small workshop or a large factory, you’ve got a power solution that feels like it was made just for you. Sensors and smart tech make these panels super efficient, cutting down on energy waste and saving money in the long run. Imagine a system that adjusts the power supply in real-time, based on what machineries are in use – that’s the smartness we’re talking about. Plus, with the latest tech, troubleshooting and maintenance become easier, meaning less downtime and more productivity. Clearly, technology is not just changing the game; it’s completely redefining it.

Benefits of Implementing Custom Power Distribution Panels

Custom power distribution panels offer a game-changer advantage for manufacturing plants. They cut through inefficiencies like a hot knife through butter. Here’s how they mix up the game: First off, they’re tailored. This means every switch, button, and indicator is where you need it to be, slashing the time it takes to get things done. Think of a suit tailored to fit you perfectly, versus grabbing one off the rack; the difference is night and day. Secondly, these panels turbocharge productivity. With everything customized to your operation’s needs, your machinery works smoother, faster, and with less downtime. It’s akin to fine-tuning a race car for peak performance. Plus, they’re safety boosters. Custom panels are designed with your specific safety requirements in mind, reducing the risk of accidents and ensuring compliance with regulations. Last, they’re future-proof. Upgrading or scaling your operations becomes simpler when your power distribution is made to adapt. In a nutshell, custom power distribution panels are not just an expense; they’re an investment in making your manufacturing plant leaner, safer, and ready for the future.

Case Studies: Success Stories in Different Industries

Industries across the board are experiencing the revolutionary impact of custom power distribution panels. Let’s look at a few standout examples. In the automotive sector, a leading car manufacturer overhauled its production line with customized panels. This adjustment cut downtime by a staggering 40% and increased output by 25%. Efficiency isn’t just a buzzword here; it’s a tangible result of smart power management. In the world of pharmaceuticals, precision and safety are non-negotiable. A top pharmaceutical company integrated custom panels to streamline its processes. The result? A 30% improvement in energy efficiency and a significant reduction in waste, making their operation greener and more cost-effective. Regarding renewable energy, a solar power company utilized custom panels to manage and distribute power more effectively across its grid. This innovation led to a 50% boost in energy distribution efficiency, proving that custom solutions are key to advancing sustainable energy technologies. These case studies underscore a simple truth: custom power distribution panels are not just changing the game; they’re setting new standards across industries.

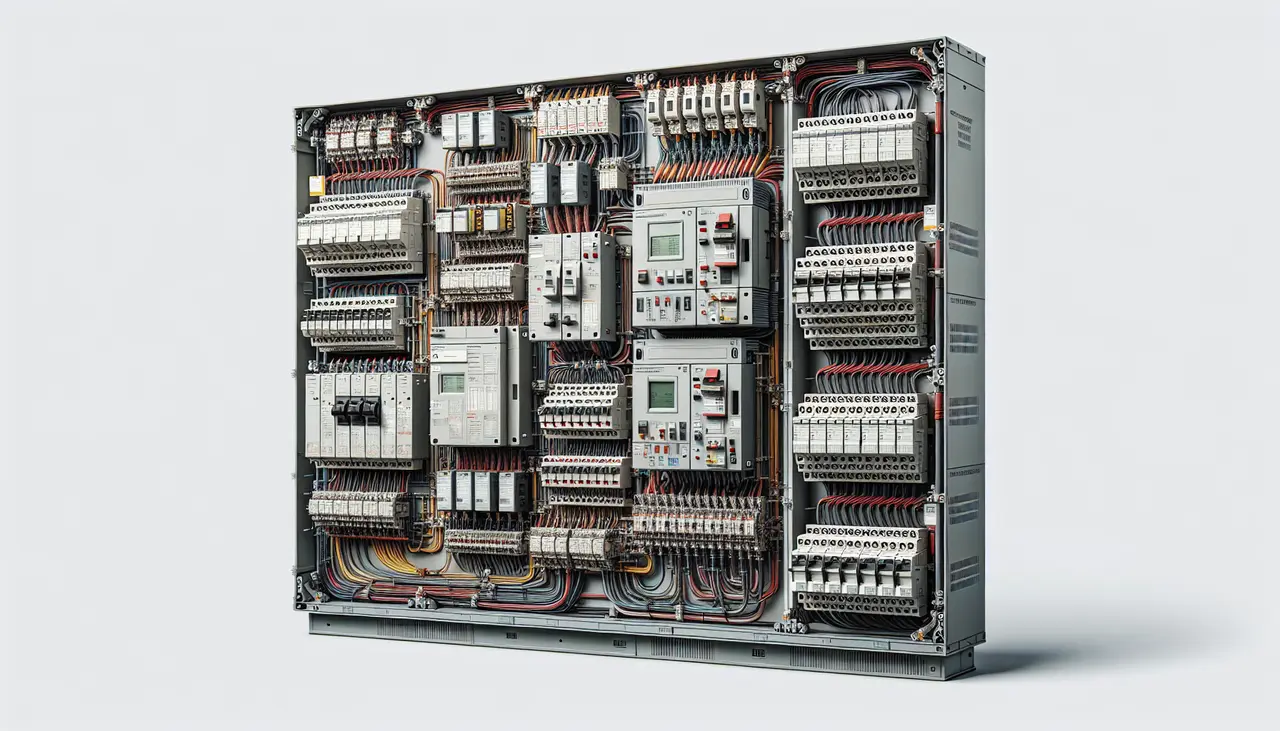

Design and Installation Considerations for Custom Panels

When it comes to custom power distribution panels in manufacturing, the design and installation of these systems are critical. The first thing to know is that every panel is unique, designed to meet the specific needs of a facility. This means considering the amount of power required, the machinery that needs to be connected, and any future expansions. The design phase is where you figure out the layout and wiring to ensure efficiency and safety. Keep it simple yet precise—overcomplication leads to errors. Once the design is locked down, installation is the next big step. It’s not just about connecting wires; it’s about integrating the panel seamlessly into your existing operations without disrupting production. This often requires working closely with engineers and technicians to minimize downtime. Remember, a well-designed and correctly installed custom power distribution panel can significantly boost a manufacturing operation’s efficiency and reliability. So, it’s worth taking the time to get it right.

Future Trends in Power Distribution for Manufacturing

The world of manufacturing is gearing up for some big changes, all thanks to advancements in power distribution. One of the most interesting trends is the shift towards custom power distribution panels. These panels are tailor-made to fit the unique needs of different manufacturing setups, improving efficiency and reducing waste. Smart technology is also making its way into power distribution, with systems that can predict maintenance needs and automatically adjust power supply to match demand. This means less downtime and more productivity. Another trend on the horizon is sustainability. With a growing push for greener manufacturing processes, power distribution panels are being designed to operate with renewable energy sources in mind, cutting down on carbon footprints. Plus, with the rise of Industry 4.0, the incorporation of IoT (Internet of Things) into power panels is enabling real-time monitoring and control over the manufacturing process, paving the way for smarter, more connected factories. So, what we’re seeing is not just an evolution in how power is distributed, but a revolution in how manufacturing as a whole is approached.

Conclusion: The Impact of Customization on Manufacturing’s Landscape

Custom power distribution panels are not just another addition to the manufacturing world; they are revolutionizing it. By allowing for precise control and distribution of power based on specific needs, these panels are making factories more efficient and productive. Gone are the days of one-size-fits-all solutions. Now, manufacturers can tailor their power distribution to match their unique processes, reducing waste and increasing uptime. This level of customization means that small and large manufacturers alike can optimize their operations like never before. As factories become smarter and more connected, the role of custom power distribution panels will only grow, cementing their impact on the manufacturing landscape. In the end, it’s about pushing limits, innovating, and creating a more sustainable and efficient future for manufacturing.