How Industrial Temperature Control Can Impact Energy Efficiency in Big Facilities

Introduction to industrial temperature control

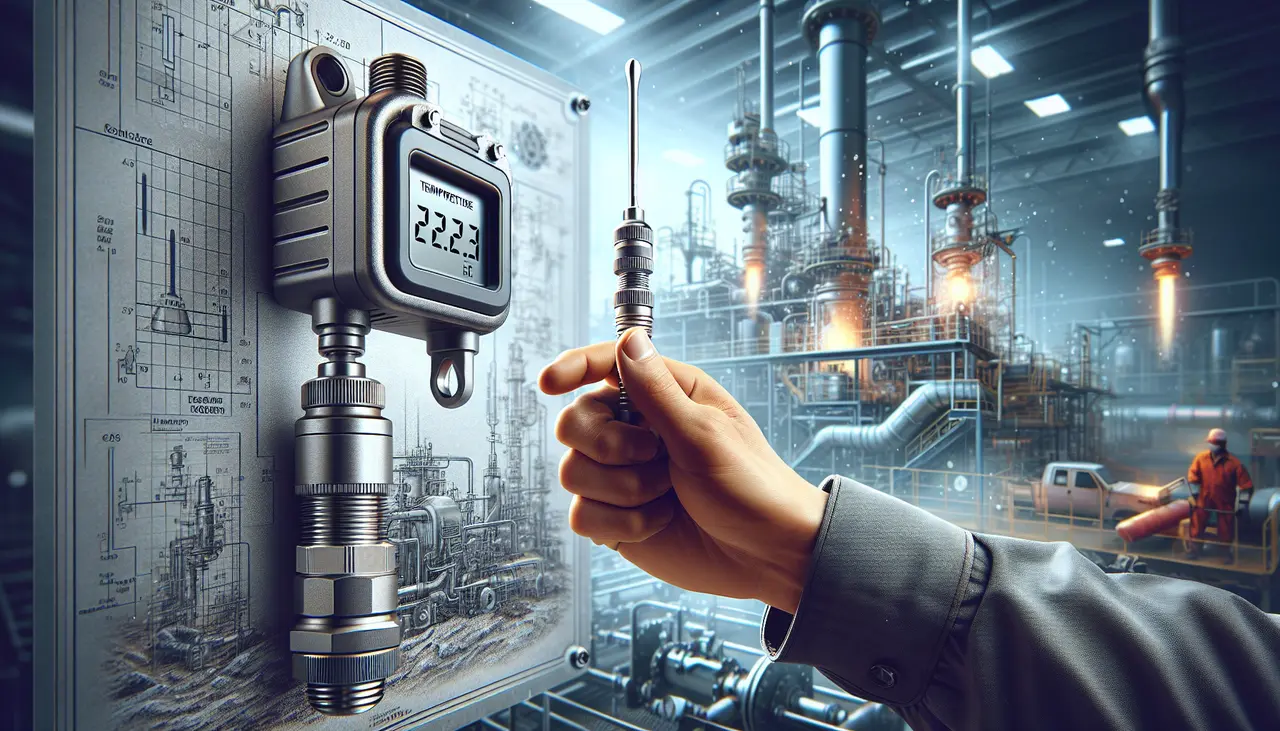

Industrial temperature control is the backbone of energy efficiency in large facilities. Think factories, power plants, or any big building that needs a constant temperature to run smoothly. This system is all about keeping the temperature just right – not too hot, not too cold. If it’s off, even by a little, it can mean big energy waste and higher bills. The secret sauce in industrial temperature control is using technology and strategies that adjust the temperature automatically. Smart sensors and controllers play a big game here, reacting to changes in real-time. So, it’s like having a thermostat that’s always one step ahead. This isn’t just about comfort; it’s about saving energy and money. Keeping things at the right temperature without using more power than needed makes a massive difference in energy bills and helps the planet too.

Understanding energy efficiency in large facilities

Energy efficiency in large facilities isn’t just a buzzword; it’s a vital factor in reducing operational costs and environmental impact. Big facilities, think manufacturing plants, warehouses, or data centers, consume a considerable amount of energy. The goal? Use less energy to do the same job. It’s all about getting the most bang for your buck.

Here’s the deal: Improving energy efficiency means closely monitoring and managing the temperature within these huge spaces. Why? Because temperature control plays a huge role in the overall energy consumption. For instance, keeping a manufacturing plant at the right temperature ensures machines work efficiently and safely. In data centers, proper cooling prevents overheating and protects critical tech equipment.

But it’s not just about comfort or safety. It’s also about the bottom line. Efficient temperature control systems can significantly cut down energy bills. They make sure you’re not wasting energy (and money) overheating in the winter or overcooling in the summer.

To boil it down, understanding and improving energy efficiency in large facilities is key. It affects operational costs, sustainability goals, and even the reliability of the processes that keep these places running. And at the heart of this efficiency? Effective temperature control strategies.

The role of industrial temperature control in energy savings

Industrial temperature control is a big player in reducing energy use in large facilities. It’s like turning off the lights when you leave a room but on a much bigger scale. When factories or warehouses manage their temperature smartly, they use less power. This is because they’re not overheating in winter or overcooling in summer. Here’s the rundown: Keeping a constant, optimal temperature means machines work less hard, and that saves energy. Say a machine is designed to operate best at 20°C. If the facility is too hot, the machine overheats and works harder, gulping down power. If it’s too cold, the machine might need extra energy to warm up or work properly. Either way, it’s wasting energy.

Moreover, keeping employees comfortable without wasting energy is a balancing act. Too hot, and you’re paying to blast air conditioning. Too cold, and it’s the heater working overtime. Smart temperature controls find the sweet spot—good for people, great for energy bills.

In a nutshell, better temperature control means big energy savings for large facilities. It’s a win-win, reducing overheads and helping the planet by cutting down on unnecessary power use.

Types of industrial temperature control systems

In big facilities, managing the temperature is crucial not just for the comfort of those inside but also for the efficiency and safety of the processes that take place there. Let’s break down the main types of industrial temperature control systems you’ll encounter. First up, we have HVAC systems. These are the big guns of temperature control, handling heating, ventilation, and air conditioning all in one. They’re essential for large spaces, keeping air fresh and at the right temperature. Next, there are cooling towers. These are used mainly in manufacturing or mechanical processes. They remove heat from the system and release it into the atmosphere, helping to keep machinery from overheating. Chillers make the list too. They cool fluids, usually water, and then circulate these chilled fluids through a system to draw away heat. This is critical in processes requiring precise temperature control to function correctly. Heat exchangers are another key type. These systems transfer heat between two or more fluids without letting them mix. They can heat or cool depending on the process needs and are versatile tools in an industrial setting. Lastly, we’ve got thermostatic controls. These are more about precision, allowing for fine-tuning of temperatures in specific areas or processes. Each system has its role, and picking the right one can make a huge difference in energy efficiency for big facilities. Stick to what’s needed, and always aim for systems that match your facility’s specific demands.

Factors affecting the choice of temperature control systems

Choosing the right temperature control system for a big facility isn’t just about keeping the space warm or cool. It’s crucial for energy efficiency and saving money. Here’s what matters: System Type – Not all systems are the same. Some use more energy to do the same job. Facility Size – Larger spaces need systems that can handle the load without wasting energy. Insulation Quality – Good insulation means your system doesn’t have to work as hard, saving energy. Local Climate – The outside temperature impacts your choice. Hot, cold, or variable climates need different systems. Energy Sources – Electric, gas, or renewable? Your energy source can affect efficiency and running costs. Picking the right system depends on balancing these factors for your specific needs. It’s about finding the sweet spot where the system is just right for your facility, saving energy, and cutting costs without sacrificing comfort.

Strategies for optimizing temperature control for energy efficiency

Getting the temperature right in big buildings isn’t just about keeping people comfy; it’s also a smart way to save on energy bills. Here’s the lowdown on making your facility more energy-efficient with some smart temperature control strategies. First up, upgrade to a smart thermostat. This little gadget learns your building’s habits and adjusts the temperature accordingly, meaning you’re only using energy when you need to. Next, keep your HVAC system in check. Regular maintenance prevents energy wastage from clogged filters or leaky ducts. Then, consider zoning your space. Not all parts of a building need to be the same temperature all the time. With zoning, you can customize temperature control for different areas, saving a lot of energy. Also, insulation is key. Properly insulating the building means your heating or cooling system doesn’t have to work overtime to maintain temperature. Lastly, make use of natural light and heat. Sometimes, the best temperature control comes from simply opening or shading windows and making the most of the sunlight. Implementing these strategies can seriously cut down your energy costs and make your facility much kinder to the planet.

The impact of improper temperature control on energy costs

Improper temperature control is like leaving a window open all winter long while your heating is on max. It doesn’t just make your facility uncomfortable; it shoots your energy bills through the roof. When temperatures swing widely because you’re not managing them well, your heating or cooling system works overtime. Imagine your system as a sprinter that’s being asked to run a marathon at a sprint pace – it’s going to burn out quickly and cost a lot in the process.

Here’s the kicker: Facilities that don’t keep a tight rein on temperature can see their energy costs go up by a whopping 20% to 30%. Yes, you read that right. It’s not just about feeling too hot or too cold; it’s about cold, hard cash slipping through your fingers.

But it’s not all doom and gloom. This just highlights the potential savings on the table if you get your temperature control in check. By simply paying attention to and adjusting your temperature settings, and ensuring your systems are efficient and well-maintained, you can reduce those energy bills. The saving isn’t chump change; it’s the real deal.

Real-world examples of temperature control improving energy efficiency

Big facilities, think factories or warehouses, chew through energy like there’s no tomorrow. But when they get smart about temperature control, the game changes. For instance, a large automotive manufacturing plant in Detroit revamped its temperature control systems. By installing advanced sensors and automated controls, they slashed their energy use by 20%. That’s a lot of power (and money) saved.

Then there’s the case of a food distribution center in California. They used to cool the whole facility to keep a small percentage of perishable goods fresh. After segmenting the cooling areas and implementing targeted temperature controls, their energy consumption dropped by 15%. More efficient, less waste.

And it’s not just about cooling. A data center in Texas, where servers generate enough heat to fry an egg, introduced dynamic temperature control solutions. These systems adjust cooling based on real-time data from the server loads, reducing their cooling costs by an impressive 25%.

These examples highlight a clear message: getting smarter with temperature control isn’t just good for the planet; it’s great for the bottom line.

Challenges in implementing effective temperature control solutions

Managing temperature in big facilities is tough. You’re trying to aim for energy efficiency but hurdles stand in your way. Things like the size of your building, different types of areas needing different temps, and the age of your HVAC systems. Let’s not forget, updating to the latest tech can be pricey and some old buildings just aren’t ready for that. Plus, the energy market changes. Costs go up, making planning hard. And if you’re trying to be more eco-friendly, finding the right balance between saving power and keeping things at the right temperature is a challenge. In short, it’s a tricky game of juggling cost, comfort, sustainability, and adapting to new tech.

Conclusion and future outlook on industrial temperature control and energy efficiency

As we wrap up, remember that the way industries control temperature plays a big role in how much energy they use. The smarter the system, the lower the energy bill and the happier our planet. Technology is changing the game. With advancements in sensors and automation, factories are getting better at keeping temperatures just right without wasting energy. Looking ahead, expect things to get even greener. Innovations like AI and smart grids will make industrial temperature control even more efficient. So, the future is bright for big facilities aiming to cut costs and reduce their carbon footprint.